First of all, anybody considering doing a dual tcase setup using a single married case, and a divorced case behind it; change your mind and heed my words - Save your money for a doubler! The amount of brain power required to make this work is more than surprising, its painfully criminal! But I've made headway, not enough to have it installed under the truck yet, but it has been test fitted into place. Its seems that every time I crawl under the M37, I manage to invent a new problem to solve. Anyway, I'll let the pictures speak for themselves...

Here is the finished mount. The Tcase mounts are done, but the frame mounting points needed some attention.

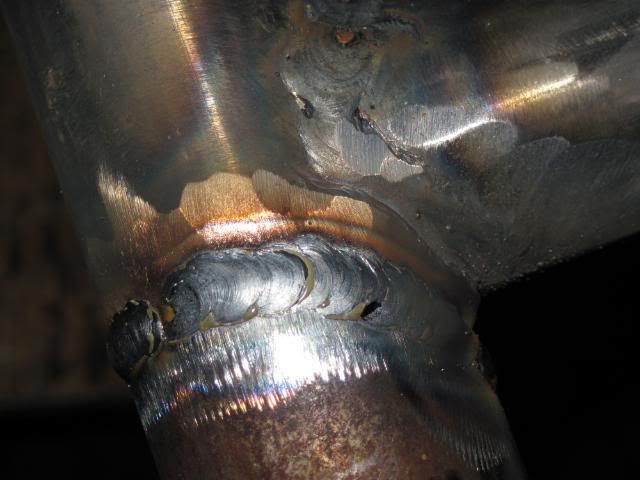

I had to cut off both the front mounts to narrow them, and redesign the setup to match the rears. I sleeved the tubing with a solid slug and welded it in place.

Then I used a small piece of scrap tubing to sleeve the outside so that it would match the diameter of the remaining tubing, and then welded them in place on either side.

After getting the mounts welded on, I had the empty framework again under the truck, only to discover that I needed to lower the setup so that it wouldn't hit the floor under the cab. I fabbed up four spacers from 1.5" square tube to space the mount downward (thats what the yellow blocks are on the framework).

Heres the setup is going into position...

Gotta love milk crates - (Diff jack - balanced 2x12 - balanced milk crate - balanced 2x6 - all balancing 200lb. NP205 and mount setup!)

It was at this point that I determined that with only 7" between the D20 output, and Np205 input, there really wasn't enough room to put a jack shaft between the two. Unfortunately I couldn't move the 205 further to rear due to a very massive crossmember in the way... (Or could I?)

Now you see it, now you don't - due to the fantastic science behind a plasma cutter, the offending cross member is no longer offending me... I will build a new crossmember once the tcase and rear end is installed. I need to ensure that the crossmember won't interfere with the drive shaft...

Thats as far as I've gotten to actually mount the setup under the truck. I had to pull it out again to make a few modifications and design some shifter brackets for shifting the 205.

Here is the first bracket, its just 3/16ths x 2" angle iron that I cut, bent and welded to follow the general bend of the tube.

Here it is welded and installed on the tube.

If you're wondering how its going to shift the 205, I've decided to forgo the typical rod and linkage setup for shifting and use a cable setup instead. Its easier to mount the shifters, and I won't have almost 15' of steel rods under the truck to get damaged or bent... Once my other shift cable shows up, I should be able to finish mount the setup, and move on to bigger and better things, like the rear end!

Lastly, I had to build a plate to mount the parking brake lever to on the side of the transmission. Its just 3/16ths plate, and it ties into the top cover on the trans, and a trans case hole. I also put some adjustment holes in the plate so that I can angle the handle a little so that it dosen't interfere with the bottom of the dash, or the openning in the floor access panel.