Tank cover

Posted: Tue Apr 22, 2008 5:31 am

Where can you buy the tank cover that has the vent and pickup line? Also,was there a filter on the end of the intake if I have to repair this one?

Thanks.

Thanks.

Fabricating one is very simple, your truck being a '52 model didn't originally have a filter on the pick up tube. The B1 trucks did have an in tank filter however. Yours should be mounted under the hood on the front of the voltage regulator bracket. Could be in the tank though, sometimes they got changed around.M37-1952 wrote:Where can you buy the tank cover that has the vent and pickup line? Also,was there a filter on the end of the intake if I have to repair this one?

Thanks.

[/img]

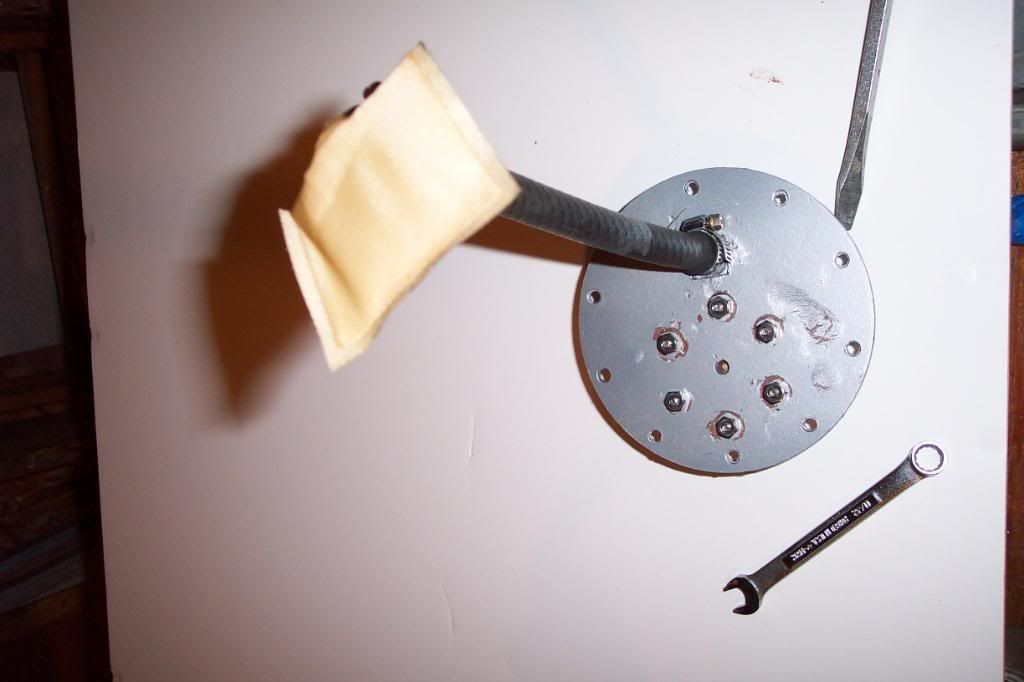

[/img]Here's what I do, cut a plug from 16 gauge plate the correct diameter using a hole saw. Drill the screw holes in correct pattern, drill the holes for the brass elbow, thread the hole with 1/4 NPT threads. Screw the elbow into the threaded hole in the plate until all the way down, snug & turned in the right direction for line attachment. Tin the plate & solder around the fittings, this gives a leak proof installation. Screw an inverted flare fitting onto the exposed male pipe thread on the under side of the plate, attach a 5/16" brake tube to the fitting cut to the correct length (about 1/2" above the bottom of the tank). Drill & attach the vent line assembly if you plan on fording. If you don't plan on fording, leave that assembly off, you won't need it. Cut a gasket from viton or neoprene rubber & install in the tank. Takes about an hour.rixm37 wrote:Charles can you explain more about fabbing a pick up tube?