Page 1 of 1

Engine Stand

Posted: Wed Nov 24, 2010 5:30 am

by jordankjcm

Has anyone used an engine stand, like the ones you get from Harbor Freight or elsewhere, to hold a T-245 block while building and painting it? It seems to me that the weight of the block would be too much for those 4 bolts to hold, or that the casting of the block would crack where the bolts attach. I can find some engine stands that rotate (nice feature!) but they are always listed for Chevy or Ford V-8, a shorter block I suppose. Any advice or experiences you all could share would be appreciated. I hope to begin to reassemble a short block soon and would like to use one of these rather than drag the block around the shop floor on a dolly. Thanks!!

Re: Engine Stand

Posted: Wed Nov 24, 2010 5:46 am

by cuz

As long as you go with a quality stand with an adequate load rating and a good balance wheel layout you will be just fine. I've been using them for over 40 years and the biggest problem with any of them has been balance. Most with the "T" base using a single wheel at the leg of the "T" are very tipsy when rolled around the shop. The modified "H" with 4 wheels behaves a little better.

Re: Engine Stand

Posted: Wed Nov 24, 2010 6:02 am

by captain kirk

I used one of the 3 wheel type and Cuz is right, it will work but you have to be very carefull, because it is a little tipsy so a 4 wheel would be better.

Re: Engine Stand

Posted: Wed Nov 24, 2010 6:59 am

by Lifer

The best engine stands for the inline 6 is a cradle type that supports the engine at both ends. When I was a kid, the local Chevy garage had several of them. Unfortunately, I haven't seen one in years.

The commonly used style these days, which attaches only at the rear are abailable in several load capacities. If using one of them, I'd recommend using one of the 4-wheel models rated to 1,250 lbs. A good one can be a bit steep, pricewise, but well worth it from a safety standpoint.

Re: Engine Stand

Posted: Wed Nov 24, 2010 7:30 am

by Josh

I have the large harbor freight one, with the "T" base, very good stand for the money. two words of caution though. IT is VERY tipsy, I almost dumped my fully dressed big block one day (so that answers your load question). Took every ounce of my strength to get it back upright, it had definitely passed the point of no return. I think adrenaline kicked in and helped me save it.

Second word of caution is that it has a collar with holes and pins in it, meant to roll the engine over to make working on the bottom of the engine easier. Be VERY careful rolling it over... Mine caught me off guard and rolled over very fast, since apparently big blocks are heavier on teh top than the bottom, and that is what threw it off balance and past the point of no return...

Other than that small faux pas, it did the job no problem, and a 400 big block weighs about 750 lbs dressed.

Re: Engine Stand

Posted: Wed Nov 24, 2010 7:36 am

by skinnedknuckles

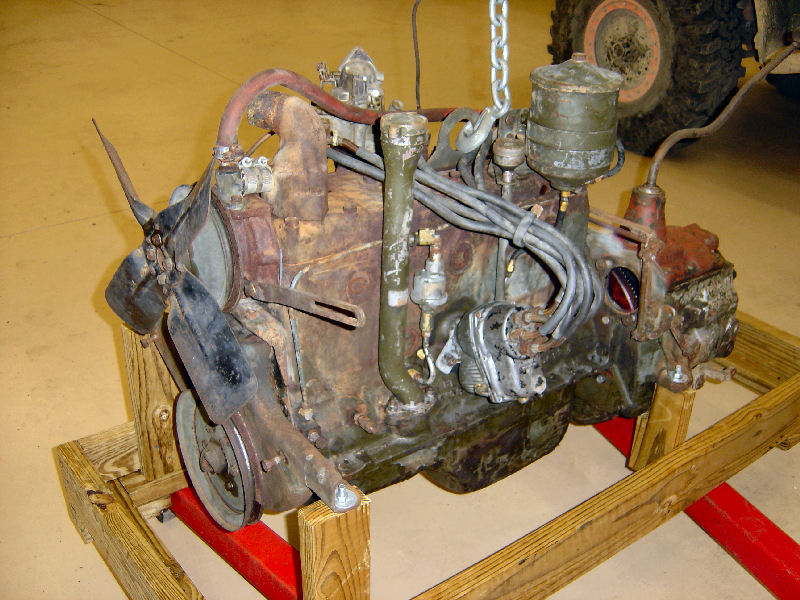

Right now my T245 engine is on one of the 4 wheel stands from Harbor Freight rated at 1250 lbs. Its the one with the "H" pattern where the wheels are mounted. I have not had any problems yet and its been on there about a month and a half waiting for me to finish up the chassis.

Re: Engine Stand

Posted: Wed Nov 24, 2010 7:39 am

by NebM37

I have a Harbor Freight 4 legged HD version that holds up a Cummins 6bt just fine, so it should handle the little six no prob.

NoRM

Re: Engine Stand

Posted: Wed Nov 24, 2010 9:32 am

by MSeriesRebuild

Stands that are available with adapters to mount the block from the side rather than the end are the most steady by far; not so much weight so far away from the actual point of mounting. These are much higher end stands than what have been mentioned, yeh I wish we had 1, but we don't.

You mentioned the possibility of breaking a casting; we have not done it as we try to use caution in mounting and be certain everything is supported well to try and eliminate any possibility; I have talked to people who were obviuosly a little negligent about paying attention that have said it happened to them, so caution should be applied if in any doubt. It isn't a question as to whether the stand is capable, but whether the casting is capable in some situations.

Re: Engine Stand

Posted: Wed Nov 24, 2010 12:48 pm

by W_A_Watson_II

I have two, and the three wheel T is indeed tipsy. Strength is also an issue, as when I had the SB327 on it I had to place a prop between the end of the motor and the stand to keep it from bending the plate and drooping. I built a wood stand to store the M's 230-L6, but that was with the bellhousing.

Re: Engine Stand

Posted: Fri Nov 26, 2010 1:45 pm

by rickv100

On a slight off topic question, has anyone ever see the type of stand they have pictured in the military 230 rebuild manual? It appears to support it from the sides.

Rick

Re: Engine Stand

Posted: Fri Nov 26, 2010 4:36 pm

by MSeriesRebuild

rickv100 wrote:On a slight off topic question, has anyone ever see the type of stand they have pictured in the military 230 rebuild manual? It appears to support it from the sides.

Rick

That is a similar type that I mentioned, it's a first class stand with rotator, and steady as a rock anyway you position it.

Re: Engine Stand

Posted: Fri Nov 26, 2010 6:31 pm

by snowdad

Anybody have a picture of that they can post? Sounds great.

Re: Engine Stand

Posted: Sat Nov 27, 2010 12:40 am

by cuz

This nice unit lists for over $6,000

Here's a nice display of many models:

http://www.nextag.com/engine-stand/compare-html