Hello all. Back after long time.

After leaving the shop In June last year, I put everything on hiatus for the summer to save some money and maybe trying to give it a fresh start in October. And because the new guys were fully busy with other customers, this also helped my idea.

I will recall in this post events that happened early last year.

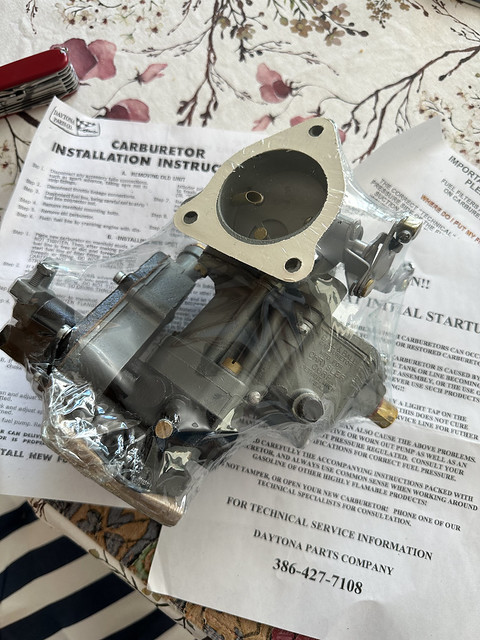

Since the problem with the pressure started, all efforts were focused on this issue. So everything was paused: brakes, electrical, carb...; just because of saving money for the worst-case scenario: engine swap.

The problem I suffer in Spain, at least where I live, is that everything takes time. I cannot control this. Blame vendors, shipping, mechanical work. Name it, but things move in a different rhythm.

Anyways, the head got on the mill again. Both surfaces, underside and top.

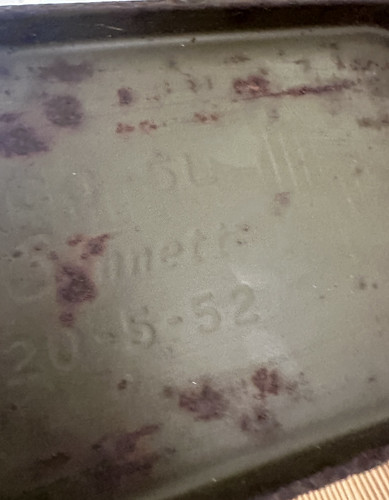

Below one can see that between cylinders #4 and #5, and #5 and #6 there is a dark trace. Same happens around the holes for the water. Of course this was now seen after the removal of the head.

After a good cleaning and applying aviation sealant the head got installed, screws adjusted following the TM and the test started.

Now, another thing happened. After running for about a minute, the radiator's inlet tube never got swollen, something that, before the milling of the head, was happening seconds after starting. This was good, but when applying the thermometer we could read 80ºC on the head and 30ºC in the outlet tube. The rad was also cold in the lower part, actually never getting any heat.

The first runs were done with no cap on the rad, so to get rid of air. I could see no turbulence when checking the filling hole so we started to think for a possible blocking. This could not be as the radiator was rebuilt and tested for pressure. So removing the water pump and inserting a water hose in the block to see the passage was the way to go; and no problem here too.

The pump had no problems. Rotated flawlessly. I don't have pictures but its inside looked good.

Now a question: what is this hole for? The pump's cover got an imprint of it and I've seen it in videos of other guys having the same marking.

Again, I don't have pictures of mine. Any idea?

The hole connects to this small orifice in the back cover of the pump. Behind where the propeller sits.

I would say it's for allowing some return to the intake current. But the hole on the block is way too big in comparison.

Anyways, one of the guys decided to drill and make the hole bigger (not too much). And it worked, the temperature got more or less in the range between hot and cold.

All this milling and testing back and forth took like a month, so when I was thinking about new steps some customers of mine decided to cut contracts. It hit me hard, the shop started getting loads of new work and the Dodge and my pace were a problem for them. We decided to stop working around April.

I'll be updating about new stuff happened since beginning of the year. See ya.